How does it work?

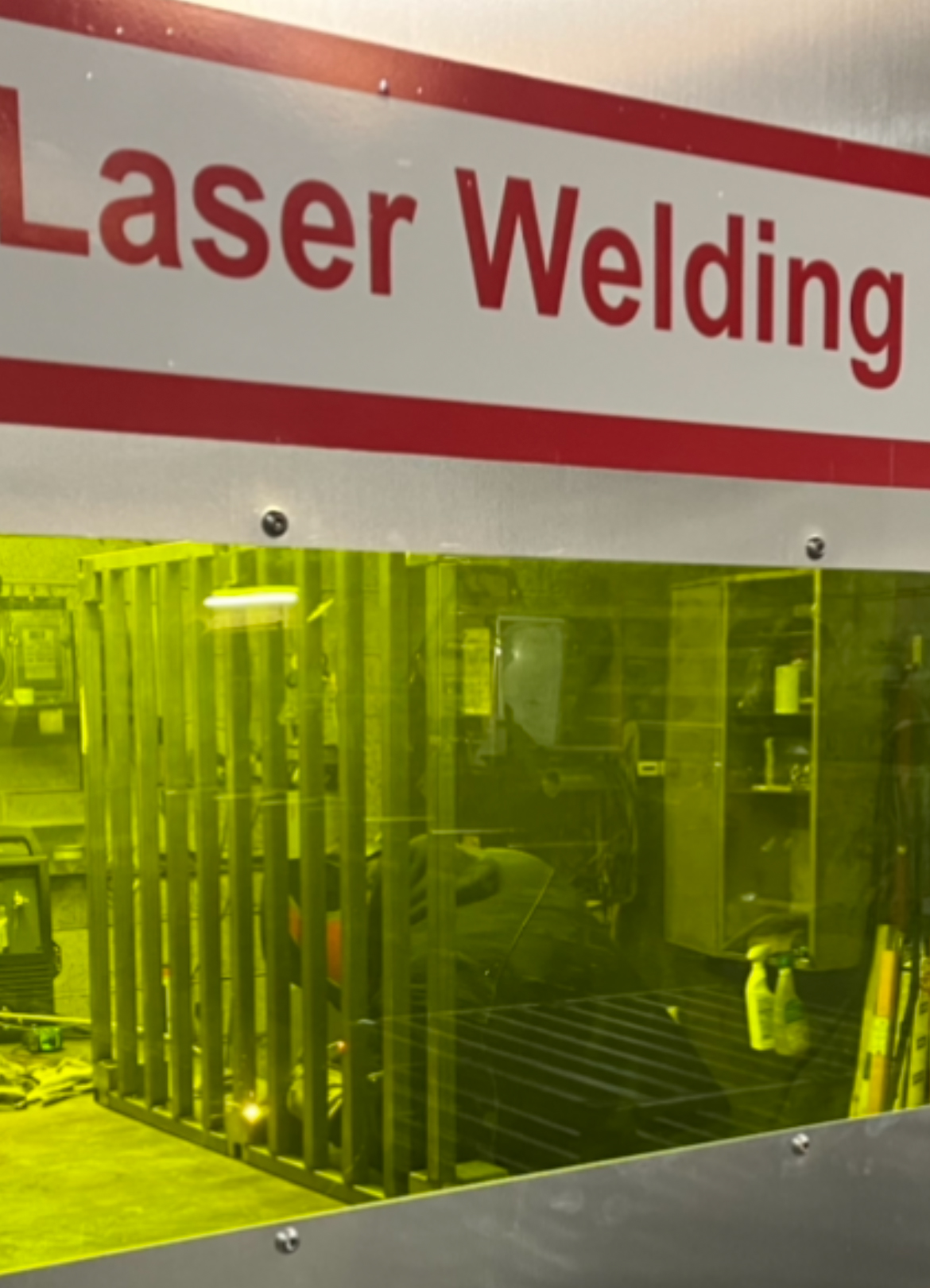

Laser welding, also known as laser beam welding (LBW), is a modern welding process that utilises a concentrated heat source in the form of a laser beam to melt materials, which fuse together as they cool.

This method is highly versatile and can weld thin materials at high speeds while achieving deep penetration throughout the material. The resulting welds exhibit exceptional strength and penetration, and are aesthetically pleasing to the eye.

Advantages of Laser Welding.

- Is approximately 3-4 times faster than a tig welder

- Has 3-4 times less heat distortion on processed parts.

- Has a finish weld quality that surpasses all other types of welding processes.

- This Means no finishing is required after the welding process.

- Has the ability to process the thinnest materials required.

- Results in a bright Weld finish free of oxides.

- Is capable of finer welds, with a much smaller heat-affected zone.

The target market for precision welding, specifically laser welding, includes individuals or businesses that require clean, precise, and high-quality welds on their products. This includes a wide range of industries such as automation, car manufacturing, aerospace, energy, electronics, medical, pharmaceuticals, and others.

Overall, any industry that relies on the production of complex and intricate components can benefit from the accuracy and efficiency offered by laser welding technology.